- Q1.

-

What is a Self Lubricating Bearings? How is it Different from a Sintered Oil Impregnated Bearings?

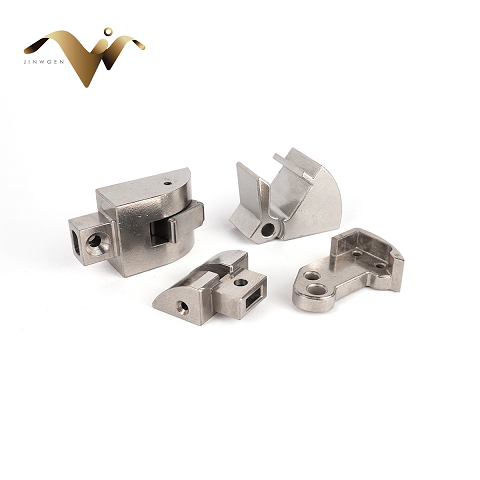

Self Lubricating Bearings vs. Sintered Oil-Impregnated Bearings | JINWOEN Expertise Self-lubricating bearings excel in maintenance-free high-load applications, while sintered oil-impregnated bearings stand out for stable oil storage and release in medium-to-low speed scenarios. With over 30 years of experience, JINWOEN offers tailored, high-performance solutions to meet diverse industrial needs.

- Q2.

-

What is Powder Metallurgy Manufacturing?

Powder Metallurgy Manufacturing combines precision, efficiency, and material versatility to produce complex metal components with minimal waste and high performance.

- Q3.

-

Processes in Powder Metallurgy

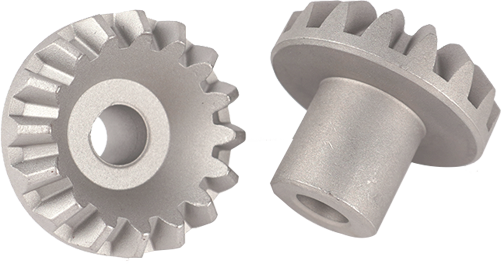

Discover the key processes in powder metallurgy, including powder preparation, compaction, sintering, and post-processing.

- Q4.

-

What is Powder Metallurgy and Why is It Important?

Discover the Power of Powder Metallurgy! Learn about Powder Metallurgy Manufacturing, its core principles, industrial applications, and the advantages it offers for cost-efficient, high-precision production. Partner with JINWOEN Powder Metallurgy, Taiwan’s leading manufacturer, to unlock sustainable and high-performance solutions for your business needs.

At JINWOEN, we provide more than powder metallurgy. Our expertise covers metal cutting, polishing, treating, rust prevention, grinding, and burnishing, offering a one-stop solution from forming to finishing.

We specialize in custom manufacturing and assembly of automotive and motorcycle components under customer specifications — ensuring precision, performance, and durability in every part we make.

JINWOEN Powder Metallurgy Co., Ltd. was founded in 1987 and specializes in powder metallurgy manufacturing. We excel in producing various precision components such as oil-impregnated bearings, stainless steel, iron-based, and copper-based parts, while also providing metal processing services. Our products are widely used across industries such as automotive, motorcycles, architectural hardware, electric and pneumatic tools, transmission gears, industrial machinery, and healthcare equipment.